Rolling Mill Equipments

End to End Solutions

Housing Less Mill Stands

Housing less mill stand is a pre-stressed stand which is more rigid than the conventional stands, the housing less stand have rigid roll chocks held together by tension screws. The roll chocks are free floating on two tension screws on each side of the mill stand, one is right hand threaded and another one is left hand threaded.

Cantilever Mill Stands

Cantilever compact stands are employed in a wide range of sizes for a vast variety of applications. Preferred fields of application are :

Advantages of Cantilever Mill Stands

The cantilever compact stands with roll shafts mounted in floating bearings have the following advantages:

Quenching System

Quenching is a critical process in metallurgy, used to rapidly cool metal and achieve desired mechanical properties. Our Quenching Box is engineered to deliver precise thermo-mechanical treatment, enhancing both strength and durability.

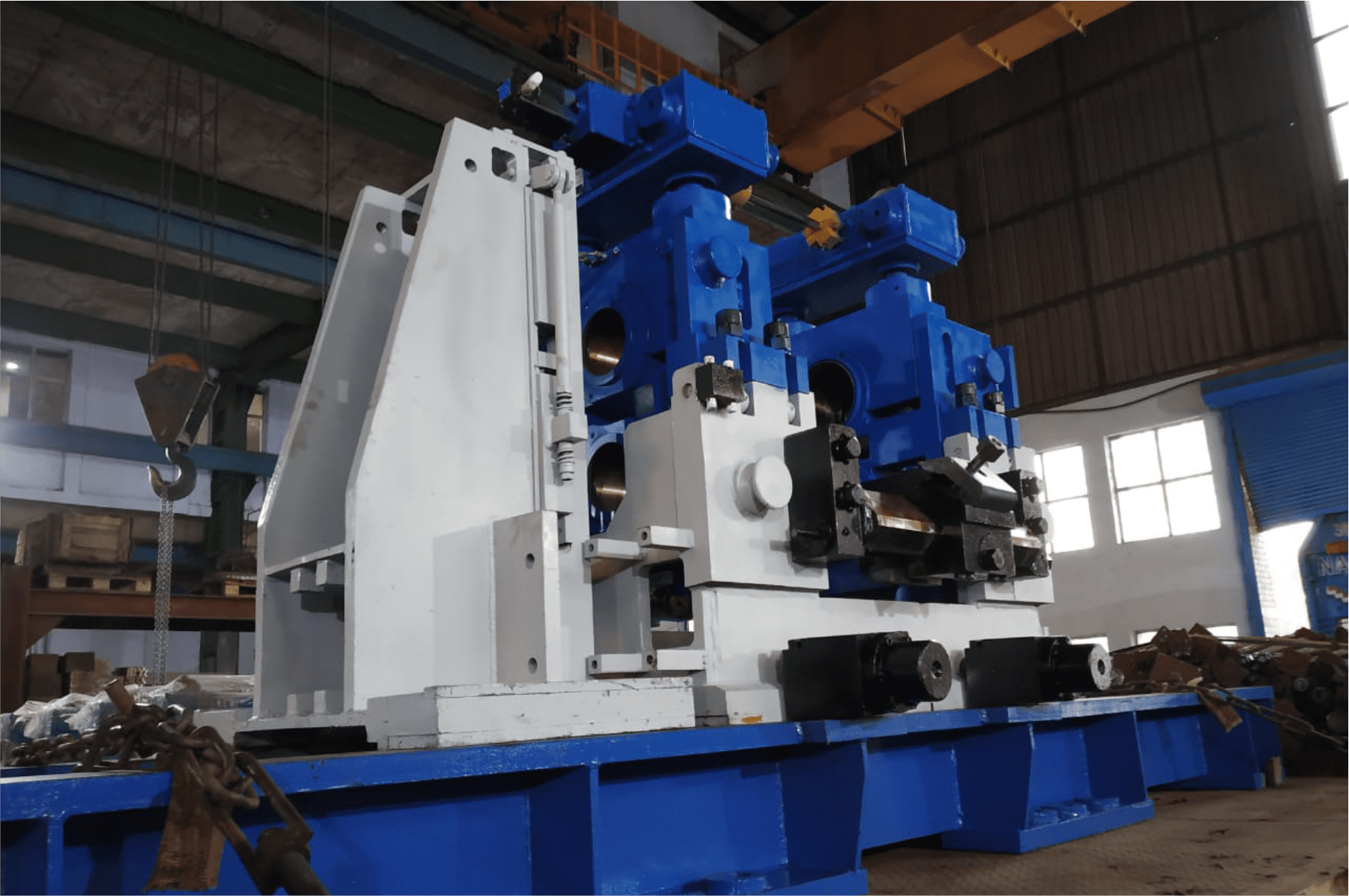

Universal Mill Stands

A universal stand is a four way rolling stand used in the rolling of section usually beams, where in the section is shaped from all four sides; the stand has sets of a horizontal & a vertical rolls, each in order to roll and shape the desired section.

Special design features

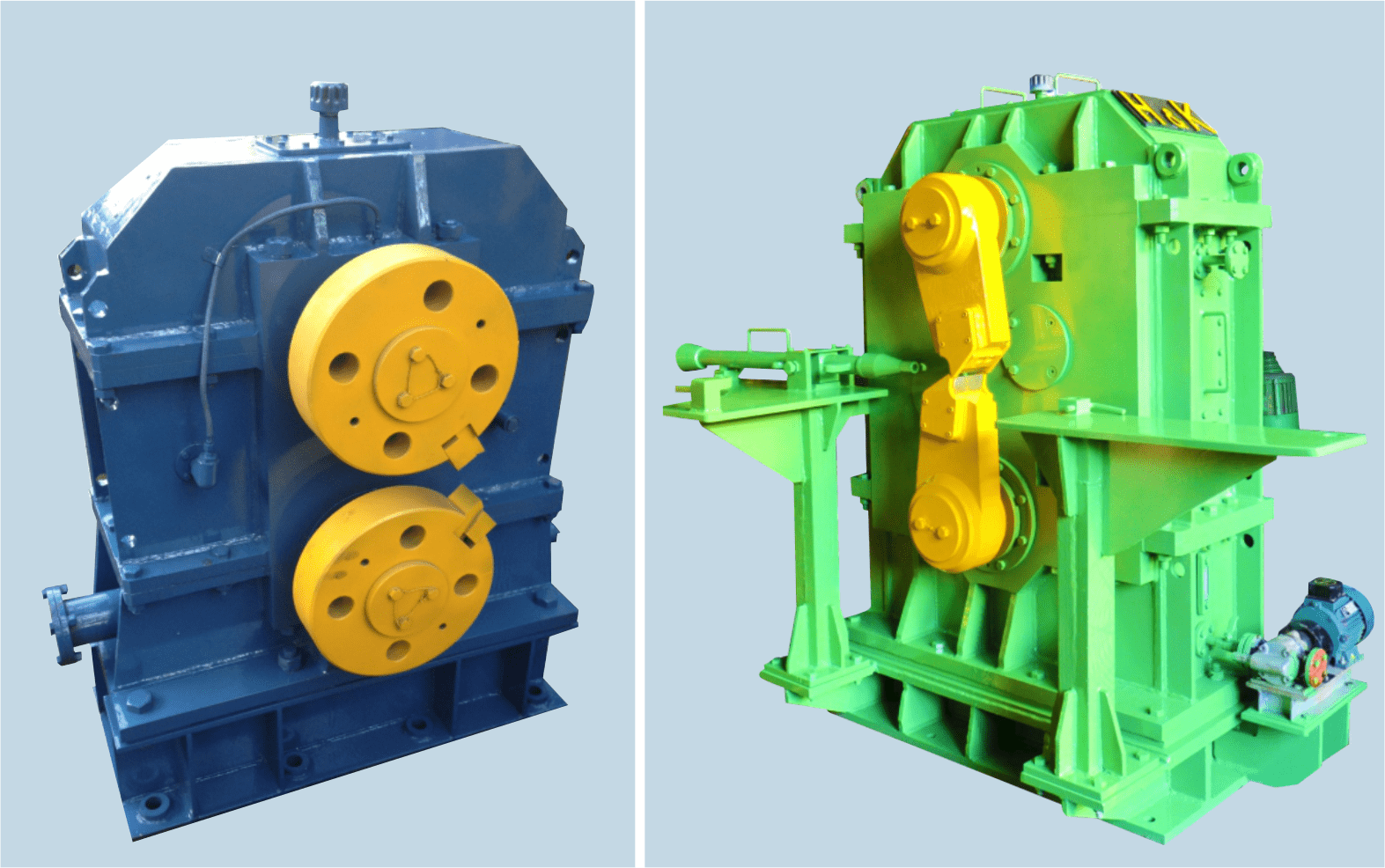

Shears

Flying Shears find their use in cutting purpose of bars. Our Shear machines are subject to customization on basis of specification. Equipped to manufacture the most advanced and highly accurate flying shears. We are known for the quality and performance of these machines.

Range of Shears

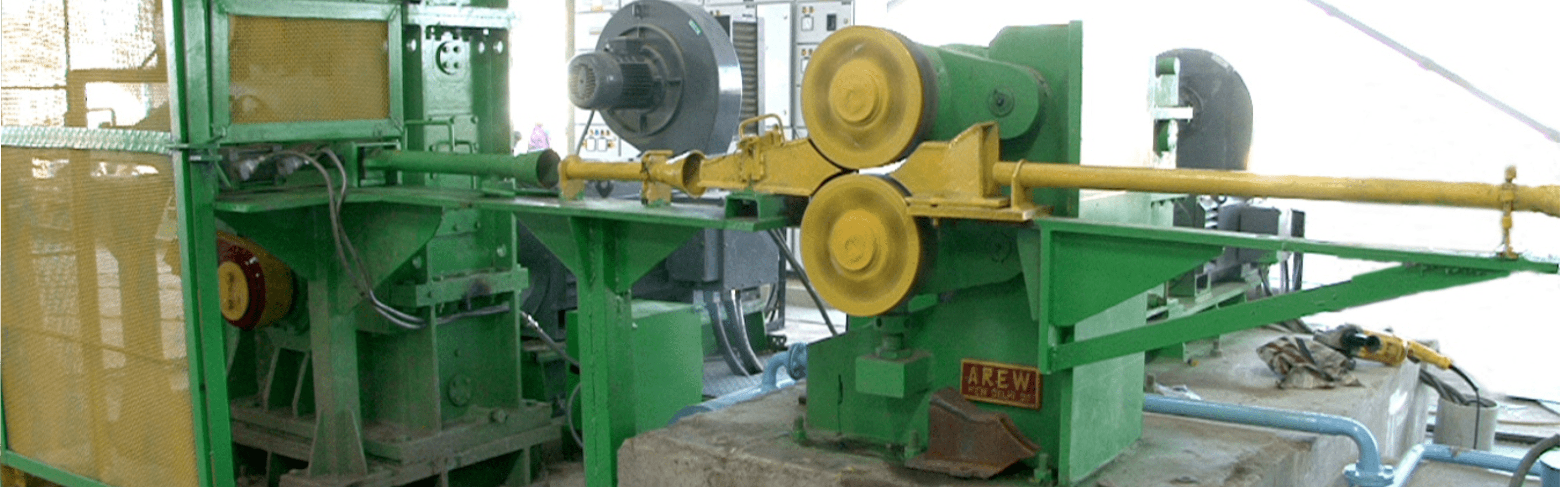

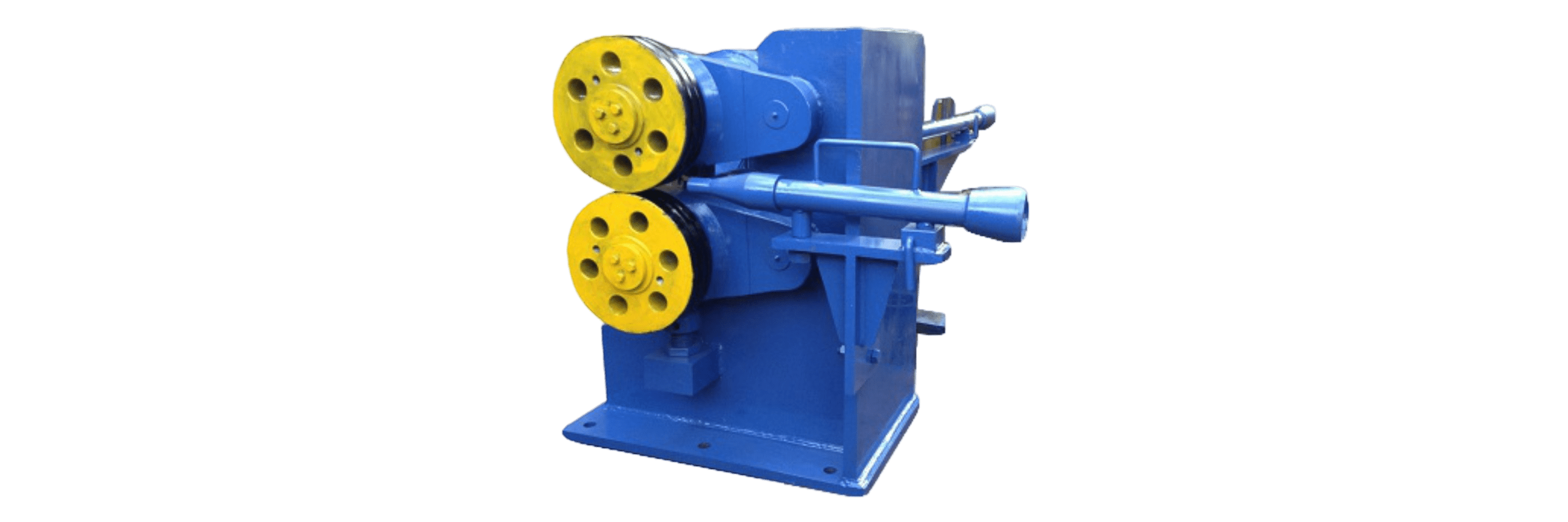

Pinch Roll & Tail Breaker

The Pinch Roll Assembly plays a crucial role in material handling between rolling stages, ensuring smooth transfer and controlled movement of hot billets, bars, or strips. It is essential for maintaining process efficiency and preventing material overrun.

Key highlights

Twin Channel

The twin channel system is an essential component in high-speed TMT bar handling, designed for safe and efficient transfer of bars post-quenching. Its robust, closed-channel design ensures both operational reliability and worker safety.

Key highlights:

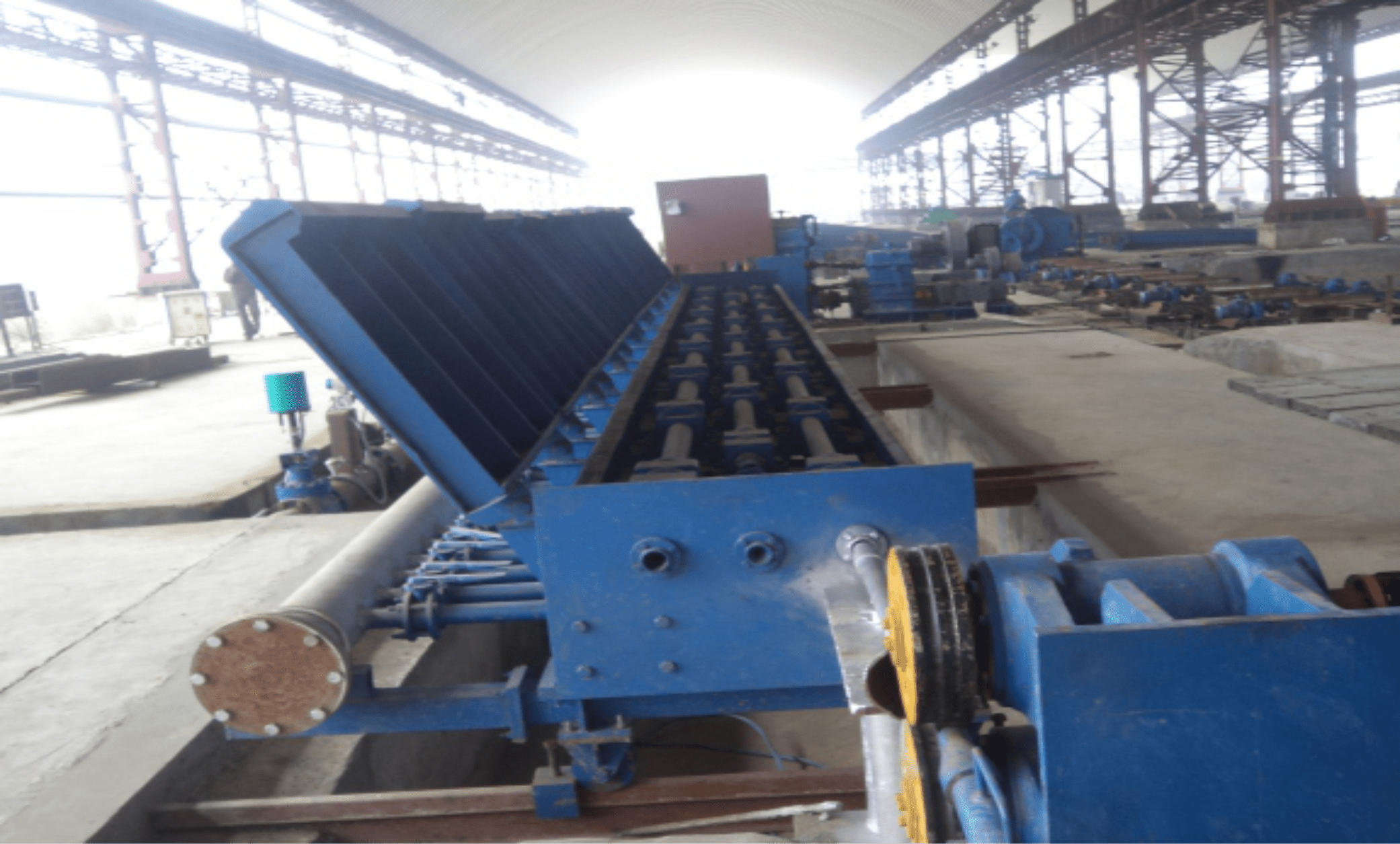

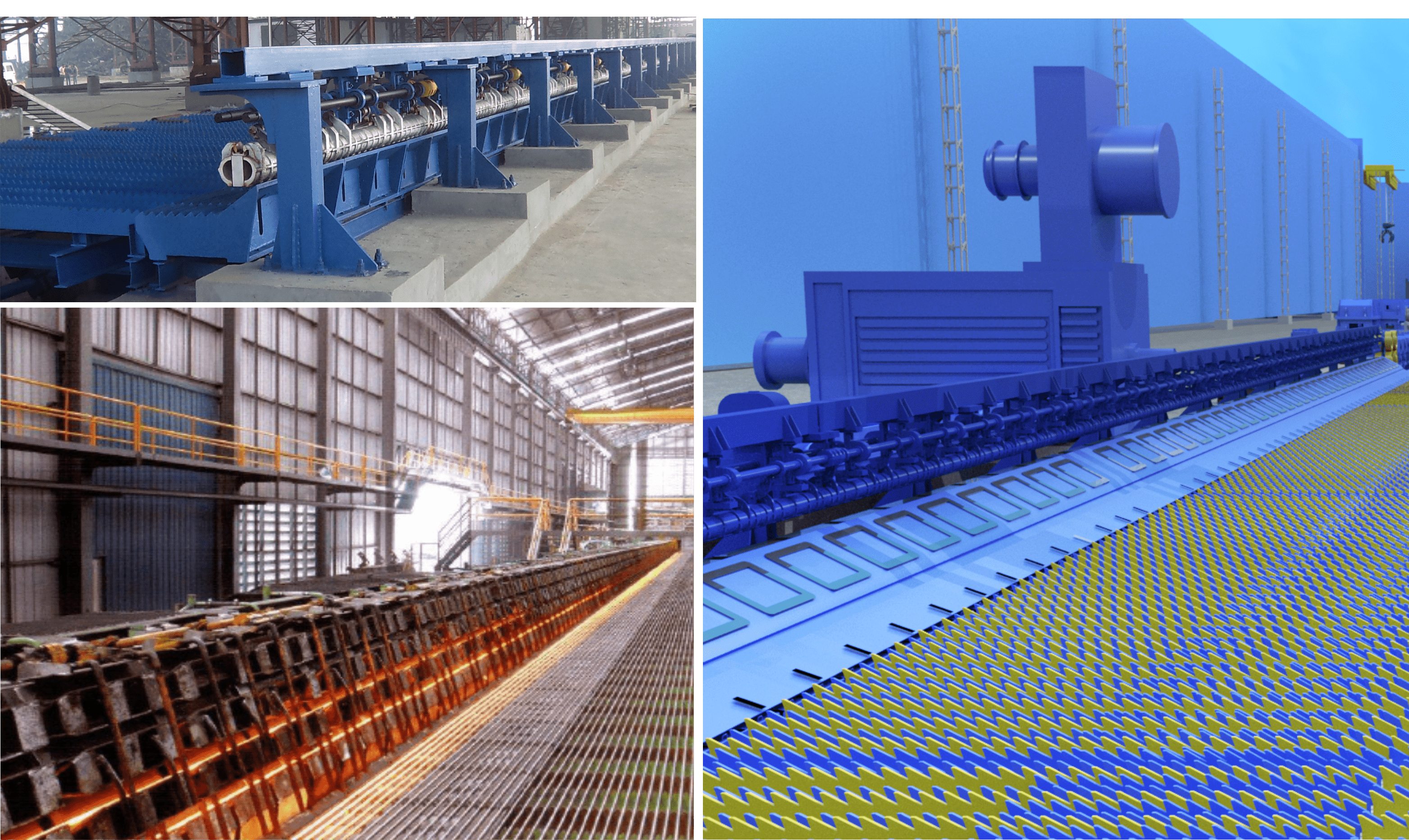

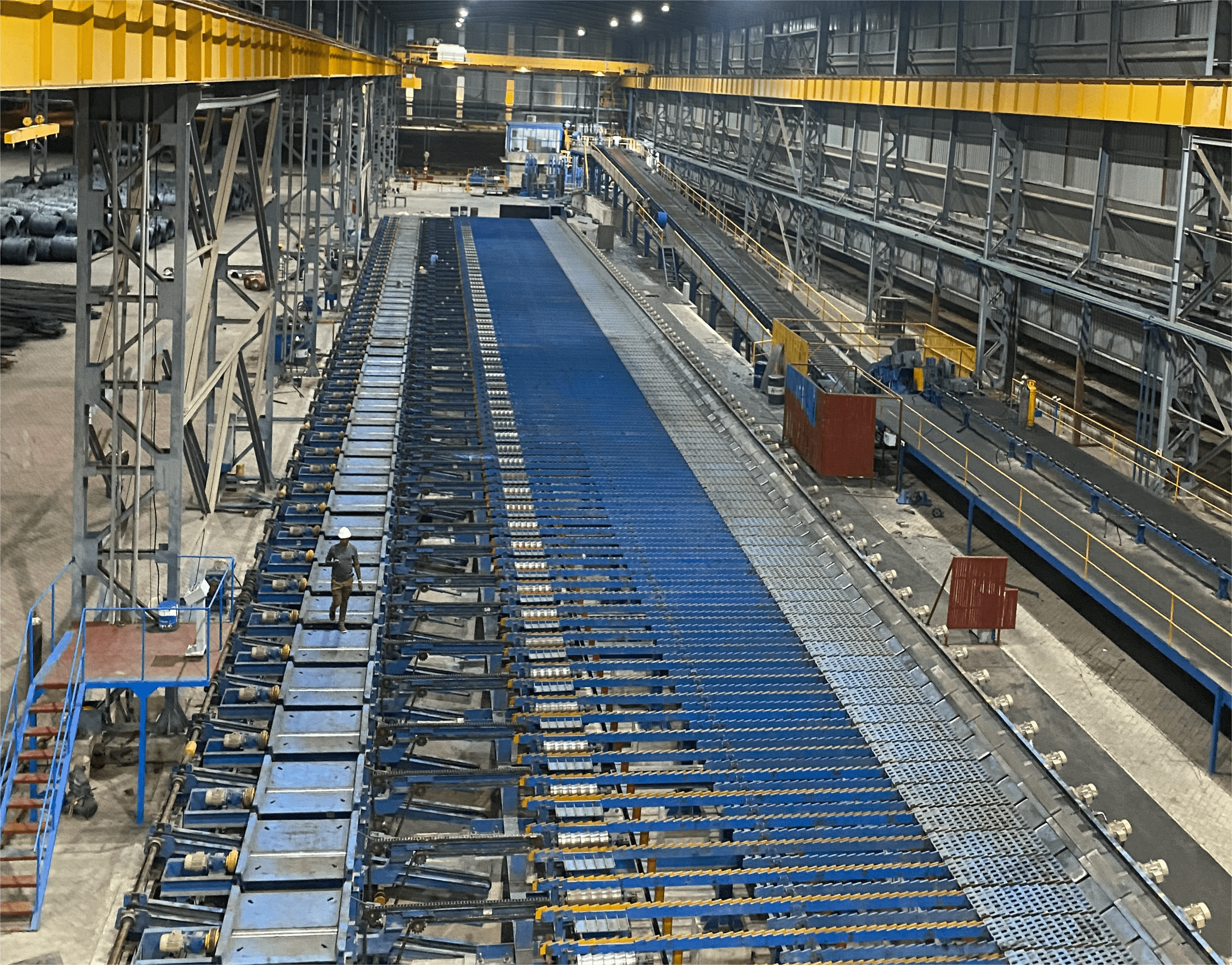

CollingBeds

Cooling beds are critical for ensuring uniform air-cooling and controlled handling of bars and profiles after rolling. Our systems are engineered for flexibility, precision, and optimal performance across a wide range of product sizes and materials.

Key highlights