Melt Shop Equipments

Efficient Melting Solutions

Melt Shop Equipments

Efficient Melting Solutions

Electric Arc Furnace – Up to 150 Tonnes

We offer advanced Electric Arc Furnace (EAF) solutions for high-capacity, high-efficiency steelmaking, engineered to meet the stringent demands of both long and flat product production. Our EAFs are designed for melt capacities up to 150 tonnes, and are ideal for both integrated and mini steel plants.

Electric Arc Furnace

Up to 150 Tonnes

We offer advanced Electric Arc Furnace (EAF) solutions for high-capacity, high-efficiency steelmaking, engineered to meet the stringent demands of both long and flat product production. Our EAFs are designed for melt capacities up to 150 tonnes, and are ideal for both integrated and mini steel plants.

Induction Furnace – Up to 50 Tonnes

We also provide Induction Furnace solutions designed for compact steel plants, specialty alloy melting, and small-to-medium capacity foundries. Our systems support melt capacities up to 50 tonnes and offer precise temperature control, minimal oxidation, and reduced environmental footprint.

Induction Furnace

Up to 50 Tonnes

We also provide Induction Furnace solutions designed for compact steel plants, specialty alloy melting, and small-to-medium capacity foundries. Our systems support melt capacities up to 50 tonnes and offer precise temperature control, minimal oxidation, and reduced environmental footprint.

Ladle Refining Furnace (LRF) -Up to 100 Tonnes

Our Ladle Refining Furnace (LRF) systems provide the essential second stage in the steelmaking process, allowing you to refine molten steel, adjust chemistry, and control temperature before casting. We design LRFs with capacities of up to 100 tonnes, equipped with robust automation and engineering to handle high-throughput, high-purity operations.

Ladle Refining Furnace (LRF) -Up to 100 Tonnes

Our Ladle Refining Furnace (LRF) systems provide the essential second stage in the steelmaking process, allowing you to refine molten steel, adjust chemistry, and control temperature before casting. We design LRFs with capacities of up to 100 tonnes, equipped with robust automation and engineering to handle high-throughput, high-purity operations.

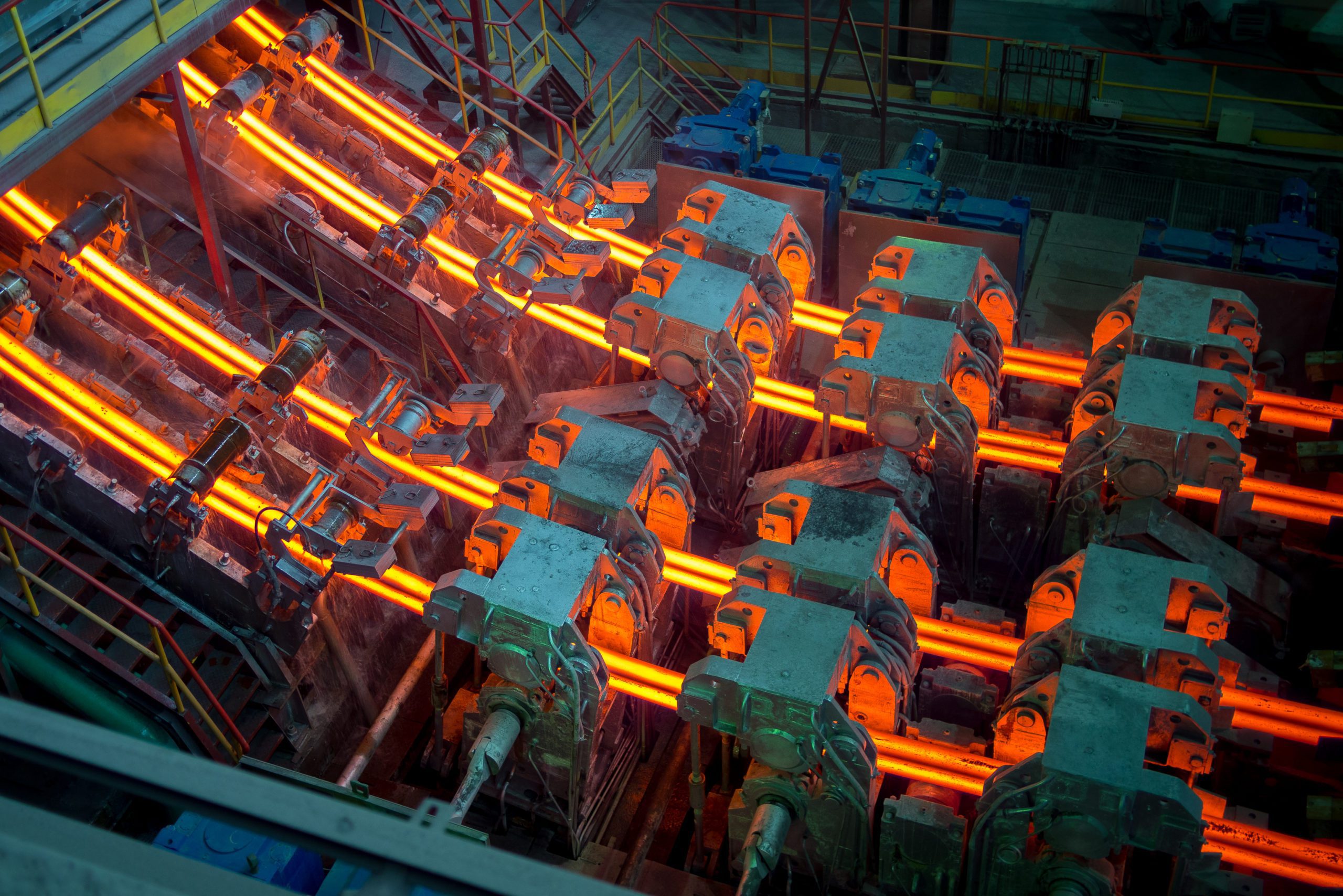

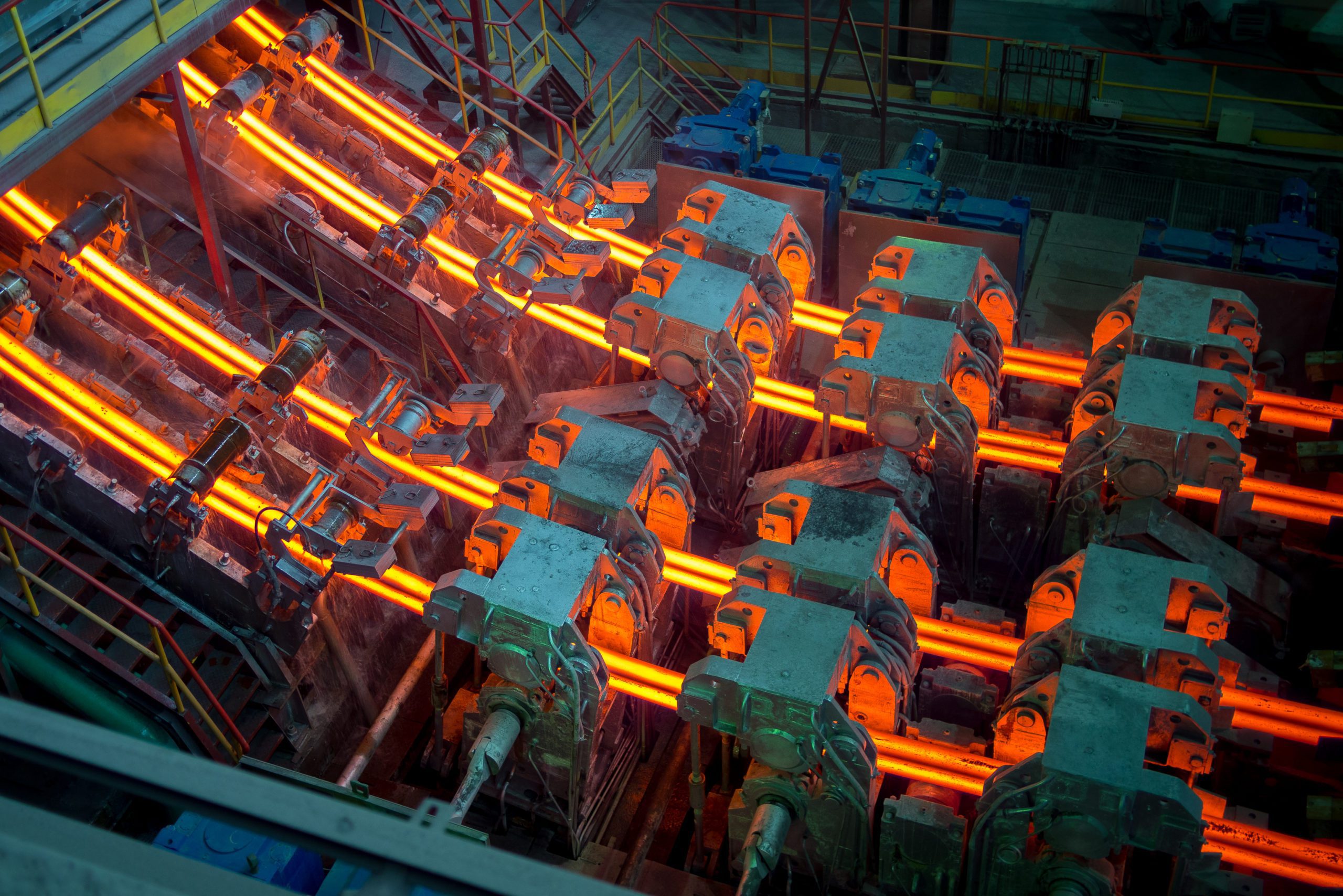

Continuous Caster Up to 1 Million TPA

We supply Continuous Casting Machines (CCM) ranging from 4/7 format to 12/23, capable of producing billets, blooms, and near-net-shape formats with annual capacities of up to 1 million tonnes. These casters are designed to match the throughput of modern melt shops and rolling mills, ensuring seamless productivity from liquid steel to solid form.

Continuous Caster Up to

1 Million TPA

We supply Continuous Casting Machines (CCM) ranging from 4/7 format to 12/23, capable of producing billets, blooms, and near-net-shape formats with annual capacities of up to 1 million tonnes. These casters are designed to match the throughput of modern melt shops and rolling mills, ensuring seamless productivity from liquid steel to solid form.

Advanced Automation and Control

Our casters feature real-time data analytics, temperature mapping, and intelligent control for optimal product shape, internal soundness, and surface quality.

Additional Equipment Supplied:

Advanced

1 Million TPA

Our casters feature real-time data analytics, temperature mapping, and intelligent control for optimal product shape, internal soundness, and surface quality.

Additional Equipment Supplied:

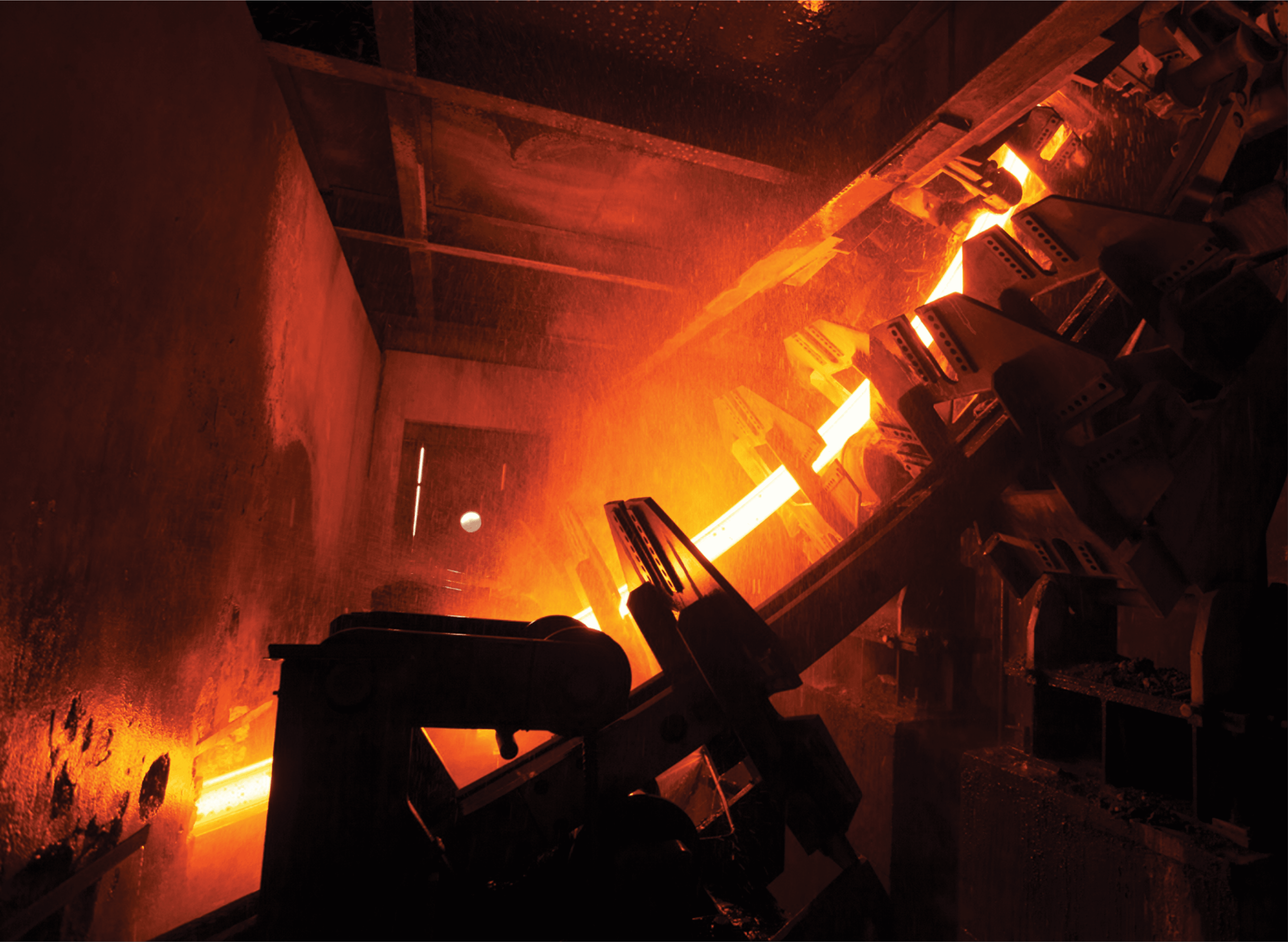

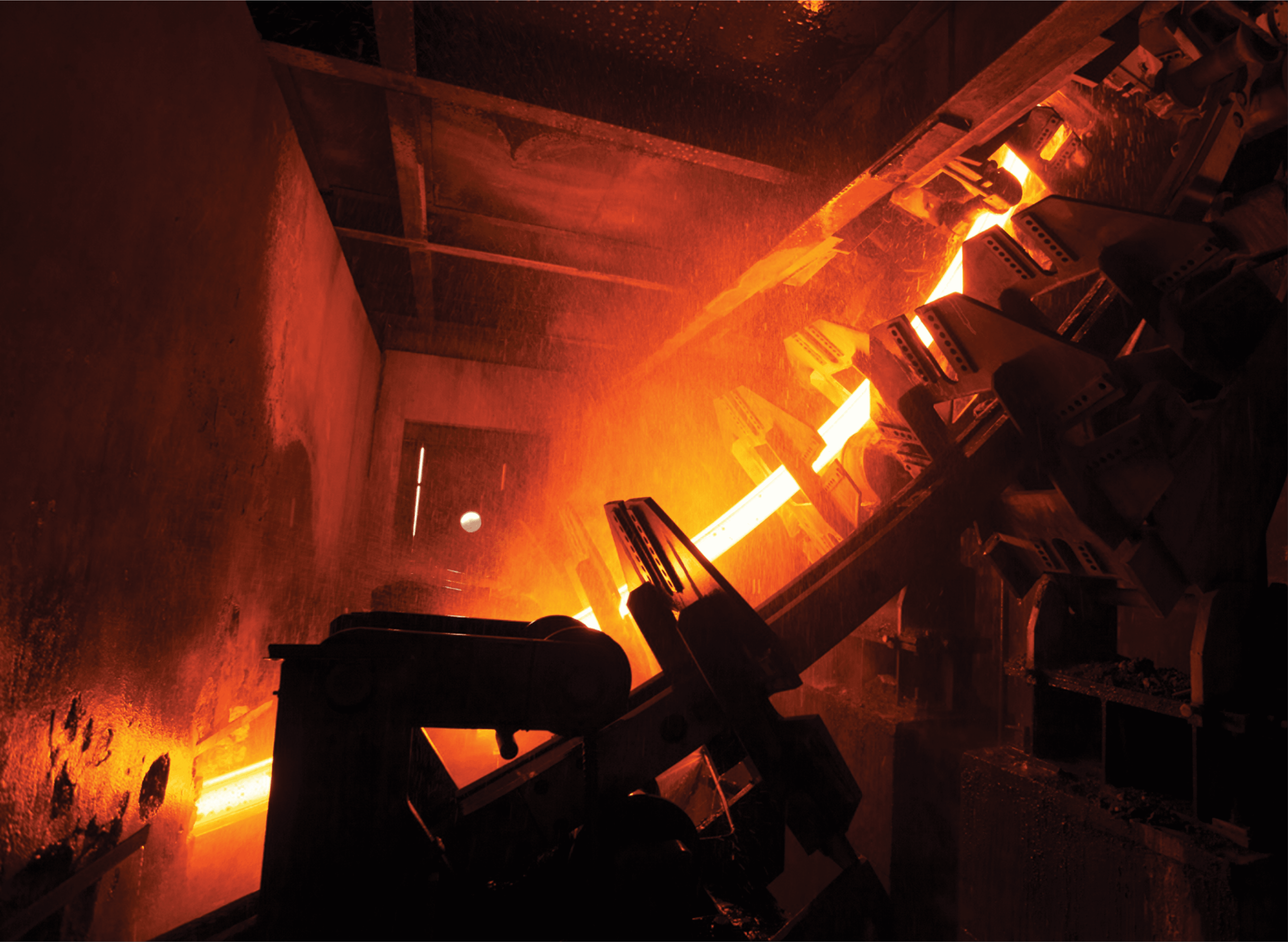

Reheating Furnace – Up to 200 TPH

World-Class Reheating Solutions in Partnership with Forsyst & Mr. Moreno De Luca

We deliver reheating furnaces with capacities up to 200 tonnes per hour (TPH) in partnership with Forsyst, one of Italy’s most innovative thermal engineering companies. These projects are led by Mr. Moreno De Luca, a globally respected authority in reheating furnace design, with a legacy of building some of the most efficient and high-performance furnaces in the world.

Reheating Furnace

Up to 200 TPH

We deliver reheating furnaces with capacities up to 200 tonnes per hour (TPH) in partnership with Forsyst, one of Italy’s most innovative thermal engineering companies. These projects are led by Mr. Moreno De Luca, a globally respected authority in reheating furnace design, with a legacy of building some of the most efficient and high-performance furnaces in the world.

Key Benefits:

Integrated Furnace Automation:

Our furnaces feature high -end PLC & SCADA-based control systems, ensuring full process transparency, safety, and control—backed by continuous technical support from Forsyst and our in-house team.

Key Benefits:

Integrated Furnace Automation:

Our furnaces feature high -end PLC & SCADA-based control systems, ensuring full process transparency, safety, and control—backed by continuous technical support from Forsyst and our in-house team.